Categorii produse

- Energy

- Battery Energy Storage Systems (BESS)

- Renewable Energy Systems

- Uninterruptible Power Supply

- Rehlko Generator Sets

- Data Centers

- Industrial Technique & Construction Machinery

- Special Offers

- Concrete vibration/finishing equipment

- Miller Welding Machines

- Concrete/asphalt cutting machines – discs

- Surface preparation equipment

- Probst paving tools and devices

- Handling technology for fully automated factories

- New machinery and tools from Probst

- Handling technology for construction material factories

- Devices for cranes

- Manipulation technology for construction material factories: pipes and inspection chambers

- Paving stones cutter

- Handling technology for construction material factories: pavers and blocks

- Installation of pre-fabricated curbs and vacuum technique

- Handling technology for construction material factories: vacuum-based technology

- Pipe assembly

- equipment for transporting stone blocks / concrete elements

- Stone/concrete tiles installation devices

- Roof mounting handling equipment

- Separation elements installation devices

- Joint filling and surface cleaning equipment

- Highway dividers installation devices

- Pavers installation and handling devices

- Mounting surface preparation equipment

- Compaction plates

- Garbage trucks

- The Green Component

- Environment

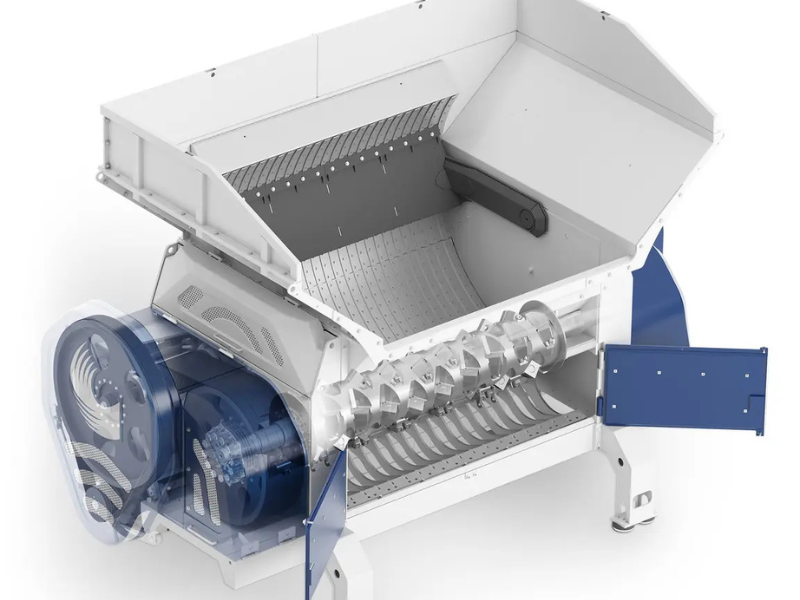

Lindner Jupiter Primary Shredder

Primary Shredding at Its Best. Reliably High Output and Consistent Particle Sizes. Jupiter 1800 | 2200 | 3200 | 2200 HP

Product Description

The Lindner Jupiter single-shaft primary shredder combines everything you need for efficient 24/7 operation: a powerful countershaft drive, a well-engineered machine design and high manufacturing quality. Undefeated by non-shreddables, our tried-and-tested technology ensures a long service life and low maintenance coupled with the necessary power to shred even the toughest materials – year after year and ton after ton.

Fire Prevention

Thats how to play it safe

Lindner’s modern out-of-the-box FPS solution automatically detects and cools over heated particles in the material stream directly on the discharge conveyor, effectively preventing possible sources of fire. The system adapts the cooling process to the hazardous situation to ensure the facility operates optimally at all times.

- Precise detection of overheated materials

- Comprehensive monitoring of the entire cooling section

- Cooling process adapted to the hazardous situation

- Independent cleaning of the infrared sensors

- Temperature resistant and robust thanks to a special insulation system

- Highly flexible modular design

Water Sprinkling System

- To remove dust from the filling area

- 4 spray nozzles positioned in the enclosed hopper

- Switch it ON/OFF using the control panel

- Machine piping incl. central water supply

- Incl. heating system & piping insulation

Bale Opener

The Jupiter BW series models impress with their low speed and powerful and precise cutting process. Plastics are shredded gently and with a low percentage of fines to an optimum DINA A4 size, making them ideal for downstream NIR sorting processes. For details contact our sales team.

High Performance

High-performance drive

- Over 50% more drive power

- Power reserve for tough materials such as

- textiles

- carpets

Input & Output Materials

- MSW

- HDPE

- C&I Waste

- Waste wood

Single-Shaft Cutting System With Four-Fold Useable Pointed Knives

- Solidly built knives and knife holders particularly resistant to non-shreddables

- Maximum availability, as knives can be changed quickly

- Easily adjustable cutting gap for optimum output quality

Countershaft Drive With Flywheel Energy Storage

Less energy consumption and more power thanks to the countershaft drive that stores and releases rotational energy depending on the load.

- Highest energy efficiency

- Consistently high throughput even with tough materials

- Spare parts obtainable worldwide

- Also available as a HP model (high performance model) for even more power and throughput

Learn more about this product by downloading the brochure bellow.

Download PDF