Categorii produse

- Energy

- Kohler Generator Sets

- Data Centers

- Battery Energy Storage Systems (BESS)

- Renewable Energy Systems

- Uninterruptible Power Supply

- Industrial Technique & Construction Machinery

- Miller Welding Machines

- Concrete/asphalt cutting machines – discs

- Surface preparation equipment

- Probst paving tools and devices

- Paving stones cutter

- Handling technology for construction material factories: pavers and blocks

- Installation of pre-fabricated curbs and vacuum technique

- Handling technology for construction material factories: vacuum-based technology

- Pipe assembly

- equipment for transporting stone blocks / concrete elements

- Stone/concrete tiles installation devices

- Roof mounting handling equipment

- Separation elements installation devices

- Joint filling and surface cleaning equipment

- Highway dividers installation devices

- Pavers installation and handling devices

- Mounting surface preparation equipment

- Handling technology for fully automated factories

- New machinery and tools from Probst

- Handling technology for construction material factories

- Devices for cranes

- Manipulation technology for construction material factories: pipes and inspection chambers

- Compaction plates

- Special Offers

- Concrete vibration/finishing equipment

- Environment

Product Description

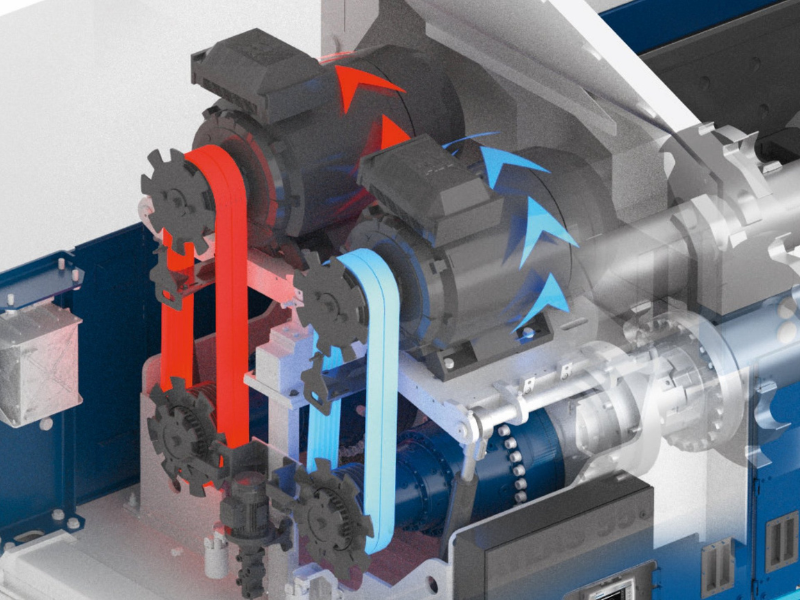

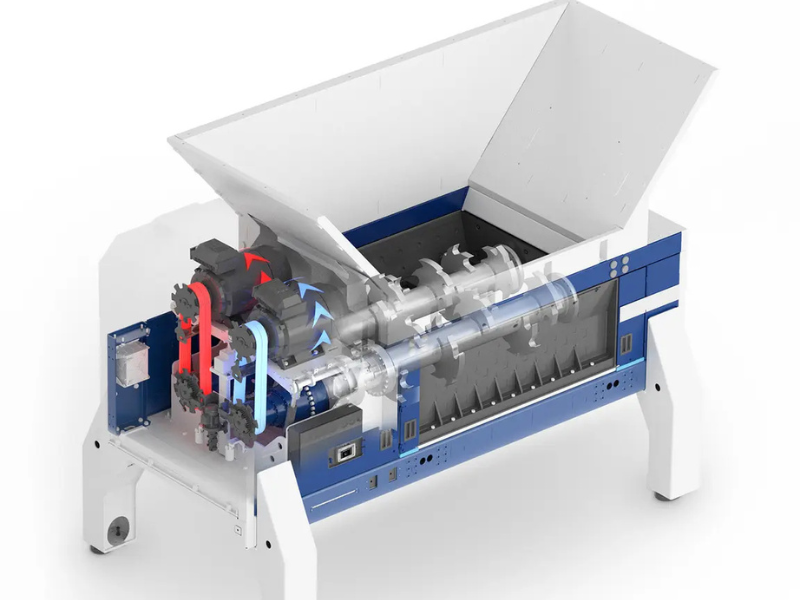

Based on the proven belt concept, the Lindner’s Atlas 5500 AS twin-shaft primary shredder sets new efficiency standards with its high-performance planetary gears, innovative DEX (Dynamic Energy Exchange) energy recovery system and asynchronous shaft control. Delivering consistently high throughput, built for tough applications and equipped with the innovative FX fast exchange system, this shredder provides maximum uptimes and can be relied on to keep the line going.

Fire Prevention

that’s how to play it safe

Lindner’s modern out-of-the-box FPS solution automatically detects and cools over heated particles in the material stream directly on the discharge conveyor, effectively preventing possible sources of fire. The system adapts the cooling process to the hazardous situation to ensure the facility operates optimally at all times.

- Precise detection of overheated materials

- Comprehensive monitoring of the entire cooling section

- Cooling process adapted to the hazardous situation

- Independent cleaning of the infrared sensors

- Temperature resistant and robust thanks to a special insulation system

- Highly flexible modular design

Water Sprinkling System

- To remove dust from the filling area

- 4 spray nozzles positioned in the enclosed hopper

- Switch it ON/OFF using the control panel

- Machine piping incl. central water supply

- Incl. heating system & piping insulation

Autom. Belt Tensioning

lindner atb – automatic belt tensioning system

- Ensures optimum power transmission at all times

- Belt exchange using a hydraulic tensioning device

- Self and preventive monitoring

Hardfacing KIT

additional wear protection package cutting system

- Ideal for shredding particularly abrasive material

- Knife hardfacing

- Scraper hardfacing

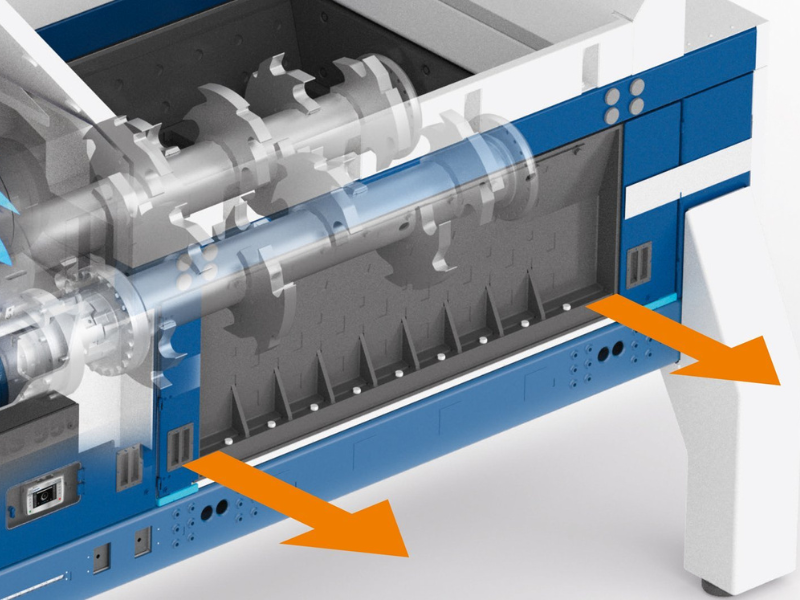

Fast Exchange System

Our unique fast exchange system (fx)

The Atlas series has been perfected to give you easy access to the cutting unit and provides two options for removing or changing the entire cutting unit or individual components. The components can be removed from the side via the hydraulically operated, swivelling slider or, after removal of the hopper, from the top.

- The cutting unit can be exchanged quickly, ensuring minimum downtime

- The two quick-change options guarantee maximum flexibility

- Easy and fast removal of the hopper

Input & output materials

- MSW

- MSW plastics

- C&I Waste

Learn more about this product by downloading the brochure bellow.

Download PDF